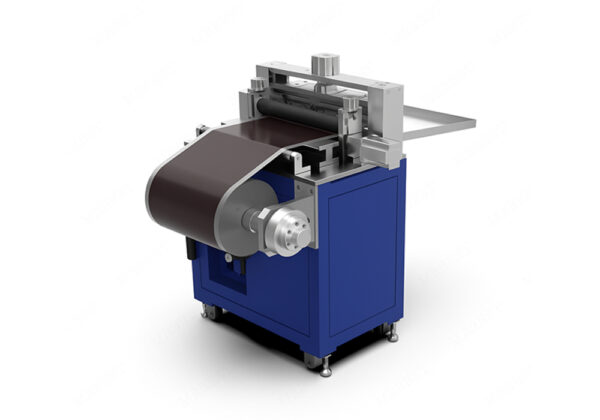

Lab Roll to Sheet Battery Electrode Cutting Machine

Need a bulk order? Request a competitive quote today!

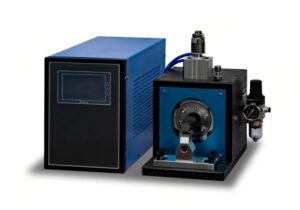

Model:XE-HQ300

Mainly used for single-chip cutting of positive and negative electrodes of lithium batteries. The cutting length, quantity and speed can be set arbitrarily. It can be cut separately. This machine has automatic unwinding function. It is controlled by the tension frame to automatically discharge and stop. The speed is adjustable when discharging, and the loading shaft is gas shaft, convenient for loading and unloading.

Features

*The cutting length, quantity and speed can be set arbitrarily, also can be cut separately;

* Automatically adjusts the tension;

*Continuous cutting, there are 2 ways are available for choose: Fixed length and Cursor tracking, suitable for multi-section cutting, and the front and back compensation at the incision can be set;

* The width is between 10~300mm, length can be set from 1~9999mm.

* This machine adopts PLC interface control, easy to operate.

* Exquisite appearance, metal adopts three-dimensional geometric design, simple and beautiful;

* Easy to operate, safe and reliable, small size;

Specifications

| Name | Automatic Cutting Machine XE-HQ300 |

| Unwinding | Automatically unwinding and constant tension. |

| Fixed length cutting speed | 5~250mm/s |

| Chasing cutting speed | 5~150mm/s |

| Unwinding diameter (Max) | 250mm |

| Burr condition | ≦25um |

| Power supply | 220V/50Hz or 110V/ 60Hz |

| Power | 1.2KW |

| Compressed air | 0.5Mpa to 0.8 Mpa |

| Scope of application | 300mm length 1 × 9999 mm cutting |

| Cutting accuracy | Fixed length using servo system and color code sensor to track fixed length, high precision, cutting accuracy within adjustable range ± 0.3mm |

| Total equipment size | L710*W710*H1000mm

(guide plate length 800mm total length 1500mm) |

| Weight | 240KG |

| Certificate | CE certificate |

| Warranty | One year limited with lifetime technical support |

Maintenance methods and precautions

- Always wipe the cross-cutting blade and guide parts to keep it clean.

- Lubricating the moving parts of guide to keep the movement smooth.

- If not use for a long time, wipe the surface of the moving parts clean and the surface should be protected by anti-rust oil.

- Regularly check the screws, nuts, pins and other fasteners in all parts of the machine to prevent loosening cause machinequality accidents and personal accidents.