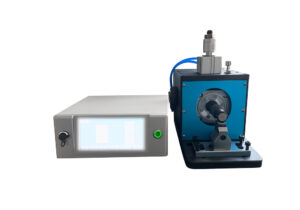

Semi-Auto Layer by Layer Stacking Machine

Need a bulk order? Request a competitive quote today!

Model:XE-BDP200-C

Product Introduction:

It is mainly used for the assembly of Z-shaped stacking of lithium battery positive, negative electrode and separator.

The device realizes manual loading, subsequent electrode position correction and stacking process by fully automatic, and has the characteristics of high stacking efficiency and high stacking precision. The device can be designed to stack up to 200*200mm batteries. Different sizes can be realized by adjusting fixtures, which is very suitable for the development and sample preparation of stacking lithium-ion batteries. The device adopts a single cantilever structure design, and the coil isolation membrane automatically controls the constant tension, and the motor drives the Separator to move left and right to realize the zigzag stacking.

Main Features:

*The number of stacking can be automatically controlled according to preset settings;

*Adopt compatibility design, the battery size change can be realized by adjusting the positioning fixture, and the adjustment range is large;

*PLC control, HMI operation, easy to use and maintain;

*Electrode manual loading, automatic positioning, automatic suction of the robot, automatic stacking;

* The Separator is forcibly guided and the Electrode is mechanically positioned to ensure high stacking accuracy;

Process Effect

| No. | Process | Picture |

| 1 | Stacking |  |

Technical Specifications

| Model | Semi-Auto Layer by Layer Stacking Machine XE-BDP200-C |

| Stacking Type | Z Type |

| Operate Method | Manual feed, robot hand take stacking material, automatic full separator, Automatic deviation correction and constant tension control |

| Working Voltage | AC220V/50Hz.(110V/60Hz) |

| Power | 1KW |

| Stacking Size | Max. L 200mm * W 200mm

Min. L 62mm * W 46mm (wihout tab) |

| Stacking Layers | Up to 500 layers |

| Max. Electrode Thickness | Max 30mm |

| Stacking Accuracy | ±0.5 mm for stacked electrodes |

| Acceptable Separator Roll Size | Max. 250mm |

| Vacuum Pump | An Oilless Vacuum pump is built-in to enable the vacuum suction function of the electrode pick-up/stacking manipulator. |

| Suggested Air Pressure | 0.5~0.8MPa argon, nitrogen gas cylinder,

or 0.7MPa compressed air (If the equipment is placed in a glove box, argon or nitrogen is required to use; if the equipment is used outside the glove box, compressed air can be used) |

| Product Dimensions | 1200 mm L x 800 mm W x 900 mm H |

| Weight | About 300 kg |

| Compliance | CE Certified |

| Warranty | One Year limited warranty with lifetime support

Rusting and damage due to improper storage condition or maintenance is not covered by warranty |

| Application Notes | Note: please confirm electrode sheet size before order (each mold only fit with one size electrode, other size can be customized separately) |

Maintenance methods and precaution

- Always wipe the swing roller and the stacking table to keep it clean.

- Lubricate the moving parts of the bearing slide rail to keep the

movement smooth.

- If it is not used for a long time, wipe the surface of the machine clean, wrap it and store it.

- Regularly check the screws, nuts, pins and other fasteners in all parts of the machine to prevent looseness and prevent machine quality accidents and personal accidents.