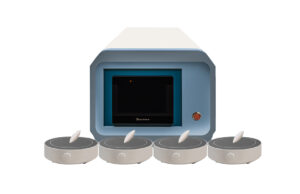

Three-Door Vacuum Drying Oven for Battery & Electrochemical Materials (XN-DVO-3)

Need a bulk order? Request a competitive quote today!

This battery vacuum drying oven is designed for lithium-ion battery and electrochemical material processing, including electrode sheet drying, electrolyte injection preparation, and vacuum sealing operations. The three-door configuration allows independent chamber control, ensuring high efficiency, process stability, and flexible batch handling for battery manufacturing and R&D environments.

Product Introduction

This equipment is designed for battery manufacturing processes, including electrode sheet drying and electrolyte injection and vacuum sealing operations.

Product Features

Temperature control adopts a three-loop PID controller, delivering high control accuracy.

After reaching the preset temperature, the vacuum chamber maintains stable vacuum or inert gas working conditions.

Three-stage temperature protection system: heating automatically shuts off if the set temperature is exceeded, ensuring material and equipment safety.

Equipped with an independent timer; the drying time starts automatically once heating begins and stops automatically at the end of the cycle.

Each temperature zone can be independently controlled and activated; circulation fans can be operated independently and used after heating stops.

Utilizes SUS stainless-steel seamless heating tubes, providing fast heating and energy efficiency.

Features a circulating hot-air vacuum chamber design to ensure uniform temperature distribution inside the chamber.

Inner chamber made of high-quality SUS stainless steel, resistant to electrolyte corrosion and battery materials.

Insulated outer enclosure with precision sealing minimizes heat loss and effectively resolves issues of heat conduction between chambers and external heat dissipation.

Chamber door equipped with dual-layer toughened glass for observation, with an overpressure protection mechanism that automatically releases pressure when internal pressure exceeds limits, ensuring safety.

The vacuum system and chamber door use high-performance sealing structures to guarantee airtightness.

Main Specifications

Working Chamber Size: H330 × W660 × L750 mm × 3 layers

Overall Dimensions: L1280 × W1150 × H1900 mm

Power Rating: 3 kW per chamber (peak power) × 3, total power 10 kW

Power Supply: Three-phase power (configurable to local standards)

Process Gas Configuration:

Vacuum: −0.095 to −0.1 MPa

Compressed Air: 0.4–0.5 MPa

Dry Gas (N₂): 0.1–0.2 MPa

Operating Temperature: Ambient to 150 °C

Temperature Control Accuracy: ±1 °C

Temperature Uniformity: ±2 °C within the working chamber

Heating Rate: From ambient (25 °C) to 80 °C within 30 minutes

Heating Method: Electric heating with forced hot-air circulation; independent control for each chamber

Temperature Measurement Method: Precision temperature sensing with real-time internal monitoring

Over-Temperature Protection: Independent over-temperature protection for each chamber with separate temperature alarms

Alarm Method: Audible and visual alarm with buzzer

Chamber Leak Rate: < −0.098 MPa; vacuum retention ≥96% over 24 hours

Pressure Release Speed: Chamber vacuum and atmospheric pressure equalization time <1 minute

Chamber Material: SUS stainless steel plate

Exterior Material: Cold-rolled steel plate with painted surface finish

Net Weight: 700 kg