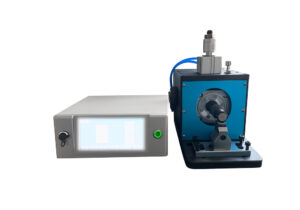

Semi-Automatic Z-Fold Electrode Stacking Machine for Pouch Cells (XN-SKMF-100)

Need a bulk order? Request a competitive quote today!

Product Introduction

This machine is mainly used for Z-fold stacking of battery cathode electrodes, anode electrodes, and separators. Electrode loading is performed manually, while electrode position correction and the entire stacking process are completed automatically. The system offers high stacking efficiency and accuracy. Different battery sizes can be realized by adjusting positioning fixtures, making it highly suitable for R&D and sample fabrication of stacked pouch lithium-ion batteries. The equipment features a desktop structure and can be operated inside a glovebox. It adopts a single-arm structure with automatic constant-tension control for roll-type separators.

Product Features

Automatic constant-tension control for roll-type separators with Z-fold automatic stacking

Stacking quantity can be preset and automatically controlled

Modular fixture design allows battery size changes through adjustable positioning fixtures, providing a wide adjustment range and ensuring stacking accuracy

PLC control with HMI interface for easy operation and maintenance

Manual electrode loading, automatic positioning, automatic vacuum pick-up, automatic stacking, manual separator loading, and tape application

Left-right movement driven by stepper motors for high precision and convenient fine adjustment

Suitable for operation inside a glovebox

Main Specifications

Stacking Method: Z-fold stacking, roll-type separator

Operation Mode: Mechanical arm automatic electrode pick-up, automatic separator unwinding with constant tension control

Vacuum Pick-up Pressure: Better than -65 kPa

Stacking Accuracy: Overall flatness ±0.3 mm (inter-electrode alignment accuracy, based on 25 layers)

Electrode Width: 40–90 mm

Electrode Length: 40–100 mm (electrode direction, excluding tabs)

Electrode Tab Length: Max. 15 mm

Stack Thickness: Max. 15 mm, maximum stack layers configurable up to 100 layers

Maximum Separator Roll Diameter: 200 mm

Separator Core: 3-inch core with expansion chuck

Stacking Speed: Electrode stacking 4–6 s per sheet, separator stacking 6–8 s per sheet (excluding electrode preparation time)

Power Supply: Configurable according to local electrical standards

Power Consumption: 600 W

Air Supply: 0.5–0.8 MPa

Overall Dimensions: Approx. L800 × W600 × H720 mm

Net Weight: 120 kg