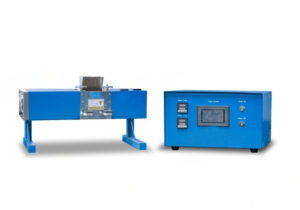

Hydraulic Calendering Machine Unwinding and Rewinding Unit XN-FSJ300

Need a bulk order? Request a competitive quote today!

Product Introduction

This automatic unwinding and rewinding unit is designed for material roll unwinding and winding. It can be integrated with a hydraulic calendering machine to realize continuous processing of battery cathode and anode electrode sheets. The system is also suitable for unwinding and rewinding of optical films, functional films, and other flexible sheet materials.

Product Features

Unwinding and rewinding adopt servo motor automatic tension control, ensuring stable and uniform winding quality.

Both unwinding and rewinding units are equipped with automatic deviation correction, providing high winding precision.

Independent electric control system enables stable and reliable operation.

Modular structure with separate unwinding and rewinding units allows flexible configuration.

Designed to work in combination with hydraulic calendering machines for integrated operation.

Main Specifications

Tension Control: Servo automatic tension control for both unwinding and rewinding

Unwinding and Rewinding Mode: Automatic deviation correction

Maximum Tension: 30 N

Maximum Rewinding Diameter: 250 mm

Calendering Machine Matching Width: ≤ 0.5 mm

Overall Dimensions:

Unwinding Unit: L410 × W790 × H530 mm

Rewinding Unit: L650 × W790 × H530 mm

Net Weight: Unwinding unit approx. 200 kg; rewinding unit approx. 237 kg

Power Supply: Configurable according to local electrical standards

Power Consumption: 1 kW

Drive Mode: Continuous operation

Guide Roller Length: 350 mm

Maximum Machine Speed: 6 m/min