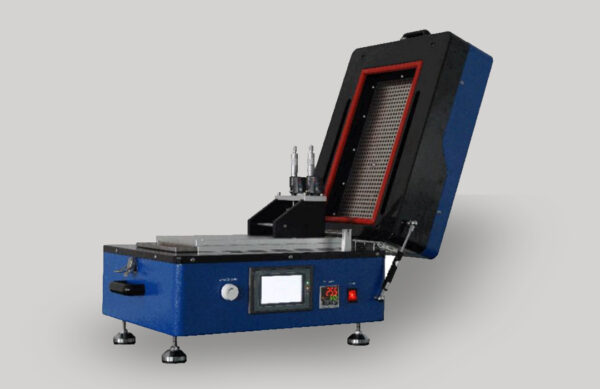

Automatic Film Coating and Drying Machine

Customization available upon request to meet your specific experimental needs.

Need a bulk order? Request a competitive quote today!

✅ Equipment Introduction

This product is widely used in research on various high-temperature coating films, such as ceramic films, crystal films, battery material films, and special nanomaterial films. It supports scientific and technological development of film formation under different experimental conditions.

✅ Functional Features

-

Utilizes large-area uniform heating to ensure high-precision temperature control inside the chamber.

-

Adopts a flat coating method, driven by a motorized pushing rod; coating speed is stable and adjustable.

-

Equipped with a vacuum plate and quick-release aluminum vacuum chuck for easy sample pickup; aluminum foil, copper foil, and other substrates can be attached to the internal or external vacuum source for fixing, with adjustable fixtures for different substrates.

-

Comes with a film applicator for precise control of coating thickness and uniformity.

-

Can be used in glove boxes, suitable for small external dimensions and limited space.

-

PLC touch screen control, parameter settings are convenient and intuitive.

✅ Technical Specifications

| No. | Item | Specifications |

|---|---|---|

| 1 | Power supply | AC 110V ±10%, 50/60Hz |

| 2 | Power consumption | 1.2 kW |

| 3 | Coating method | Flat coating, standard with MR-TM100 film applicator |

| 4 | Coating speed | 0 ~ 120 mm/s (e.g., for phosphor slurry) |

| 5 | Coating thickness | Adjustable from 6 ~ 100 μm |

| 6 | Stroke length | Approx. 250 mm; stroke can be adjusted continuously without limit switches inside the vacuum chamber |

| 7 | Speed control | Motor-driven, speed adjustable continuously via touch screen |

| 8 | Doctor blade gap | 0.1 ~ 6 mm adjustable |

| 9 | Coating thickness accuracy | ±3 μm; optional surface profiler accuracy up to 1 μm |

| 10 | Vacuum plate | Vacuum aluminum plate (for easy substrate attachment) |

| 11 | Vacuum pump | One oil-free vacuum pump included |

| 12 | Vacuum plate size | L365 mm × W200 mm × H32 mm |

| 13 | Heating system | Room temperature ~150°C, digital temperature control, accuracy ±1°C |

| 14 | External dimensions | L570 mm × W440 mm × H355 mm |

| 15 | Weight | 35 kg |

✅ Packing List

| No. | Name | Qty | Unit | Notes |

|---|---|---|---|---|

| 1 | Automatic coating & drying machine | 1 | set | Model MR-TMH250 |

| 2 | User manual | 1 | copy | Paper document |

| 3 | Warranty card | 1 | copy | Paper document |

| 4 | Film applicator | 1 | set | Standard |

| 5 | Push rod | 1 | piece | Standard |

| 6 | Waste tray | 1 | piece | Standard |

| 7 | Power cord | 1 | piece | Standard |

| 8 | Allen wrench set | 1 | set | Standard |

✅ Operating Procedure

-

Place the substrate on the vacuum plate, turn on the power, start the vacuum pump, and fix the substrate onto the vacuum plate.

-

Place the film applicator on the substrate and add slurry.

-

Turn on the coating program; the film applicator and push rod will move automatically to perform uniform coating.

-

After coating is complete, cover the heating chamber, set the heating temperature and time, and start the heating and drying process.

-

Once drying is finished, open the heating cover, remove the coated substrate, and reset the equipment for the next use.

✅ Maintenance and Precautions

-

Before each operation, use a soft cloth dipped in alcohol to carefully clean the film applicator and substrate holder to keep them clean.

-

When using the applicator and micro-adjustment parts, avoid excessive force; adjust carefully to ensure even pressure on both sides.

-

Regularly check and tighten all screws, fasteners, and rotating parts to prevent loosening, damage, or accidents affecting product quality.