Battery Making Machine Electrolyte Diffusion & Degassing Chamber

Need a bulk order? Request a competitive quote today!

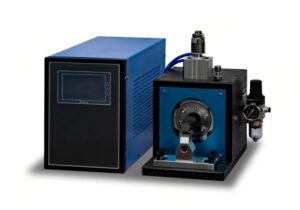

Model: XE-JZ300

XE-JZ300 electrolyte diffusion & degassing chamber is specifically designed for professional Li-ion Battery Research. It is mainly used for removing air from the electrolyte after it’s been injected into the polymer Li-ion cell or after the formation for final sealing under a vacuumed condition. It is easy to operate and suitable for all types of batteries(especially pouch cell battery and cylinder battery). Unique periods of vacuum control system allows electrolyte to thoroughly saturate the electrodes to ensure the best battery charging-discharging performance.

Features:

- Multi-stage cycles operation function makes the electrolyte absorbing more completely.

- Applicable for batteries in different sizes , adjust simply and conveniently.

- Split design of main machine and control box makes the machine can work either in glovebox or on production line.

- Trough perspective window can observe the changes inside the chamber.

- Touch screen operation , high automation.

Specifications:

| Model | Electrolyte Diffusion & Degassing Chamber XE-JZ300 |

| Inner Chamber Size | L325mm*W220mm*H170mm |

| Product Dimensions | Vacuum Box: 500mm(L) x 350mm(W) x 630mm(H)

Control Unit: 460mm(L) x 220mm(W) x 340mm(H) |

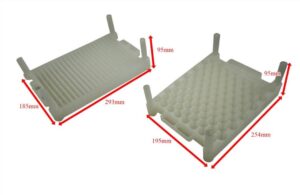

| Slot Trays (included) | Optional: Cylinder Cell Slot Tray or Pouch Cell Slot Tray

Cylinder Cell Slot Size: 20mm Dia. x 30mm Depth Tray Dimension: 254mm L x 195mm W x 95mm H Pouch Cell Slot Size: 177mm W x 30mm Depth Tray Dimension: 293mm L x 185mm W x 95mm H |

| Vacuum Level | * -90 kPa Max. (for second vacuum step, first vacuum step require -60kPa)

* Vacuum pump is required, but not included. Please contact MRBEST to order) * Vacuum condition remains stable, vacuum degree and vacuum circulation times can be set independently * Vacuum mode (once or twice) can be selected * Easy program setting for specific vacuum condition |

| Power Supply | 110-240 V, Single Phase 50/60Hz |

| Max. Power | 100W |

| Compressed Air | 0.5-0.8Mpa |

| Chamber Body | 12mm thick Aluminum case with observation window |

| Gas Filling Rate | <= 5 psi |

| Air Pressure Range | 0 – 1 Mpa (0 – 99 psi) Adjustable |

| Air Inflation Time | 0 – 99.99 sec |

| Vacuum Condition Hold Time | 0 – 99.99 sec |

| Operation Temperature | -20 to 40 ℃ |

| Warranty | One Year limited warranty with lifetime support |

| Net Weight | 50KG |

| Application Notes | 1. KF25 Feedthrough is included to allow operation inside Glove box. 2. Such a Feedthrough ensures air-tightness of glove box. |

Slot Trays for Choose