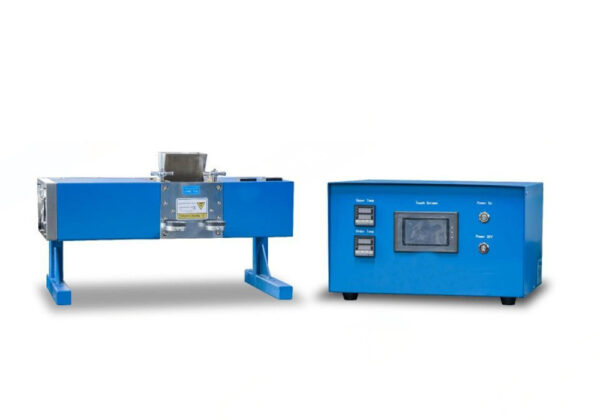

Dual-Servo Heated Flat Calendering Machine XN-HRPE200

Need a bulk order? Request a competitive quote today!

Product Introduction

This machine is mainly designed for laboratory-scale calendering of battery electrode materials and other sheet materials under controlled heating conditions. It supports electric-driven rolling with adjustable thickness and pressure, offering simple operation and stable performance. It is especially suitable for electrode densification processes, improving electrode uniformity and bulk density. The dual-servo control system enables synchronous operation with precise pressure and speed control, while rolling pressure and process parameters are digitally displayed.

Product Features

Dual-servo control provides high rolling precision and synchronous operation.

Integrated heating system allows independent temperature control of upper and lower rollers, with accurate digital display.

Roller heating ensures stable temperature control and uniform calendering results.

Adjustable rolling thickness with digital display enables intuitive and precise setting.

Rollers are made of alloy steel with precision surface treatment for high hardness and durability.

High calendering accuracy with roller roundness tolerance within ±2 μm.

Calendering pressure and rolling speed are digitally displayed for easy monitoring.

Compact and robust industrial design with refined appearance.

Electric drive enables smooth and stable operation with convenient control.

PLC control system supports automated operation with precise parameter adjustment.

Main Specifications

Upper and Lower Roller Control: Independent servo control with synchronous operation and adjustable speed

Roller Diameter: φ96 mm

Roller Roundness Tolerance: ±2 μm

Roller Surface Hardness: ≥ HRC62

Roller Surface Roughness: ≤ 0.4 μm

Rolling Thickness Range: 0–3 mm, continuously adjustable

Maximum Rolling Width: 200 mm

Roller Configuration: Horizontal arrangement

Heating Temperature: Ambient to 130 °C, adjustable

Temperature Resolution: 0.1 °C

Temperature Uniformity: ±2 °C

Drive Mode: Electric

Power Supply: Configurable according to local electrical standards

Power Consumption: 1.5 kW

Feeding Speed: 0–40 mm/s

Overall Dimensions:

Main Machine: L770 × W450 × H420 mm

Control Cabinet: L450 × W400 × H380 mm

Net Weight: 85 kg