1.XN-SFZ200 Battery heat sealing machine is a compact heating sealer for sealing aluminum-laminated films during pouch cell (polymer Li-Ion cell) case preparation.

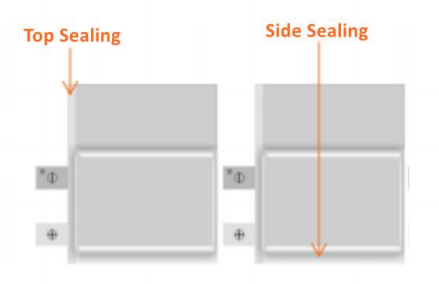

2.The battery heat sealing machine adopts soft sealing bar, The sealing is copper in bottom and aluminum and Silicone rubber piece on top. So it can be used for both top and side sealing for

pouch cell.

3.It can prepare the pouch cell for the injection of electrolyte by sealing the side and top of the pouch cell with tab.

Working principle

It is transmitted to the head (copper) through the resistance heating tube, and acts on the sealing material (aluminum laminated film) of lithium battery by using the heat conduction effect. Under a certain pressure, it is heated to become soft and close to the melting state to complete the compression fusion joint. The top seal and side seal can be realized without changing the mold.

Features

* Upper and lower sealing blade temperature can be controlled separately, temperature is

adjustable and digital display by thermostat.

* Sealing head is made from copper with good heat conduction.

* Pressure gauge is embedded and easy to observe the sealing pressure.

* Firmly sealing.

* Safety protection cover is included to avoid scalding.

* Sealing time can be adjusted by timer.

* The sealing blade length is 200mm, battery case < 200mm can be used without replacing

sealing blade.

Working Process:

Top & Side Sealing

| Category | Specifications |

|---|---|

| Model | Pouch Cell Top/Side Sealing Machine XN-SFZ200 |

| Maximum Seal Length | 200 mm Max. (customizable 200–400 mm) |

| Sealing Width | 5 mm ± 0.4 (customizable 3–10 mm) |

| Side Sealing Thickness | 60–300 μm (depending on aluminum film thickness) |

| Top Tab Edge Sealing Thickness | 200–700 μm (depending on aluminum film thickness) |

| Heat Sealing Temperature | RT–250 °C adjustable |

| Temperature Accuracy | ±2 °C |

| Sealing Time | 0–99 s adjustable |

| Seal Thickness Accuracy | Thickness difference between two points < 15 μm |

| Safety Device | Equipped with protective device to prevent high-temperature scald |

| Operation Mode | Automatic and manual operation modes |

| Flexibility | Easy to clean and replace copper mold |

| Compressed Air Requirement | 5–8 kg/cm² |

| Air Compressor Working Speed | ≥ 400 times/hour |

| Power Supply | AC 110–120 V, 60 Hz (Standard US Power) |

| Power Consumption | 0.5 kW |

| Dimensions | L 430 × W 330 × H 480 mm |

| Weight | 35 kg |

| Application Notes | Suggested Sealing Parameters: 1. Upper Heating Blade: 200 °C 2. Lower Heating Blade: 180 °C 3. Pressure: 40 psi 4. Duration: 3 seconds (operate after both dies reach set temperature) |

🔧 Recommended Sealing Workflow

For a complete pouch cell sealing process, the following combination is suggested:

- A. Compact Heating Sealer – for top & side sealing with tab

- B. Vacuum Sealing Machine – for pre-sealing in glove box after electrolyte injection

- C. Final Vacuum Sealing Machine – for vacuuming and second sealing with automatic puncture and degassing

💡 Cost-Effective Option: If budget is limited, using machine A + B can also meet basic sealing requirements.

Reviews

There are no reviews yet.