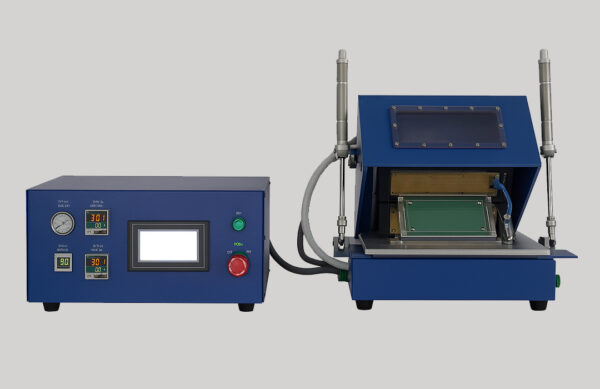

This equipment is mainly suitable for vacuum hot sealing of pouch cell after electrolyte filling and standing; the machine can automatically complete vacuum thermal sealing of aluminum laminated film by precisely controlling the main vacuum pumping box and pneumatic heat sealing components. Touch screen operation makes it high automation.

Features:

* The head is made of copper material, which has good heat transfer effect, saves power consumption, improves work efficiency and saves energy compared with similar products;

*The pressure of upper and lower heads can be adjusted by pressure regulating valve to meet the requirements of different process parameters;

*The upper and lower heads are driven by cylinder and guided by two linear guide sleeves, which can move up and down flexibly and guide accurately, ensure the requirement of parallelism after edge sealing;

* Upper and lower sealing head temperature can be adjusted separately and digital display.

*Through the perspective window, we can observe the changes in the cavity when working.

*The cover cavity is driven by cylinder and guided by rotating guide sleeve, which can move up and down flexibly and guide accurately to ensure the sealing requirements of products.

*It can be used for batteries of different specifications, and the adjustment is simple and convenient.

* Split design of sealing unit and control unit makes the equipment can work either in the glove box or the production line. KF40 feedthrough and tubes are included to allow using into

glovebox.

*Simple operation, beautiful appearance, small volume and light weight.

Working Process:

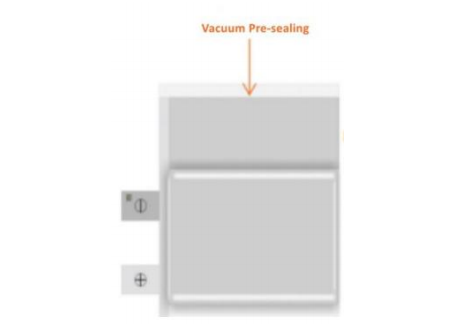

Vacuum Pre-sealing

| Category | Specifications |

|---|---|

| Name | Pouch Cell Vacuum Pre-sealing Machine XN-YF200 |

| Chamber | Made of corrosion-resistant aluminum alloy with firm structure |

| Vacuum Degree | Adjustable up to -95 kPa (buyer provides vacuum pump) |

| Head Temperature | Room temperature – 250 °C adjustable |

| Temperature Control Accuracy | ±2 °C |

| Heat Sealing Pressure | 0 – 7 kg/cm² adjustable |

| Heat Sealing Time | 0 – 99 s adjustable |

| Edge Sealing Width | 5 ± 0.4 mm (customizable) |

| Maximum Edge Sealing Length | 200 mm (customizable to 300/400/500 mm) |

| Seal Thickness Range | 60 – 300 μm |

| Seal Thickness Accuracy | Thickness difference between two points < 15 μm |

| Air Consumption | About 0.2 L compressed gas per seal |

| Working Speed of Air Compressor | ≥ 180 times/h |

| Power | Using 300 W heating tube, approx. 0.6 kW when heating |

| Power Supply | AC 110–120 V, 60 Hz (Standard US Power) |

| Compressed Air Source | 0.5 – 0.8 MPa; must use same working gas as glove box when operating inside |

| Working Chamber Size | 470 × 480 × 430 mm |

| Control Box Size | 420 × 320 × 220 mm |

| Equipment Weight | About 50 kg |

Equipment Composition

- Mechanical part: lower template mechanism, vacuum chamber mechanism, driving mechanism, guide mechanism, base mechanism, electric box control section etc.

- Electrical parts: pneumatic components, solid state relays, solenoid valves, photoelectric switches etc.

- main components:

Cylinder: AIRTAC

Bearing: NSK domestic high quality

Thermostat: Omron (imported from Japan)

Time relay: Omron

Intermediate relay: Omron (imported from Japan)

Maintenance methods and precautions

- Wipe the upper and lower plates and vacuum chamber frequently to keep them clean.

- Lubricate the moving parts of the bearing to keep it moving smoothly.

- When not use for a long time, wipe the surface of the moving parts and make it clean. The surface should be spray-protected with anti-rust oil.

- Regularly check the screws, nuts, pins and other fasteners in various parts of the machine to prevent loosening and prevent the machine Quality accidents and personal accidents.

Safe Operating Procedures

- During operation, it is strictly forbidden to extend your hands and other parts into the vacuum cavity, the moving parts of the ball guide bush, and the work dangerous area to cause

personal injury. Do not allow two or more people to operate during operation to avoid accidental injury.

Note: It has electrical protection device and safety cover, so that all moving parts are inside the cover to ensure personal safety.

- External technical personnel and external designated personnel cannot arbitrarily disassemble and debug the equipment.

- Do not disassemble circuit components without permission.

Reviews

There are no reviews yet.