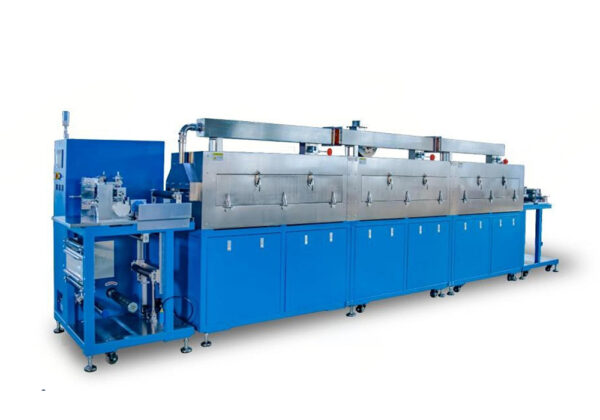

Segmented Transfer Coating Machine (Pilot-Scale, Slot-Die) – XN-RTCA-300-3

Need a bulk order? Request a competitive quote today!

Product Introduction

The Segmented Transfer Coating Machine XN-RTCA-300-3 is a pilot-scale continuous coating system designed for precision surface coating of various functional materials. It is especially suitable for lithium-ion battery electrode fabrication, enabling uniform slurry coating and controlled drying in a segmented, modular configuration. The system integrates coating, drying, and material transport into a single continuous process, offering high coating efficiency and excellent film quality. It is widely used in battery R&D, process development, and small-batch pilot production environments.

Product Features

Segmented modular drying zones allow independent temperature control for each section, enabling optimized drying profiles.

Designed for continuous roll-to-roll coating with stable transport and uniform film formation.

Supports a wide range of coating materials and substrate types, suitable for different battery electrode formulations.

High coating precision with excellent thickness uniformity and surface consistency.

Hot-air circulation drying system ensures efficient solvent evaporation and stable drying performance.

Flexible configuration allows customization of coating width, drying length, and process parameters.

PLC-based control system with touchscreen interface provides intuitive operation and real-time monitoring.

Robust mechanical structure ensures long-term stable operation in pilot-scale production.

Main Specifications

Coating Type: Continuous segmented transfer coating

Drying Zones: Multiple independently controlled heating zones (customizable length)

Temperature Control Accuracy: ±0.3 °C per zone

Drying Temperature Range: Ambient to 150 °C adjustable

Drying Method: Forced hot-air circulation drying

Coating Mode: Slot-die transfer coating with continuous operation

Effective Coating Width: 330 mm

Maximum Substrate Width: 300 mm (coating width customizable)

Coating Thickness Control: Wet thickness adjustable (typical minimum 5 μm)

Dry Film Thickness Range: Approx. 0–300 μm

Unwinding and Rewinding Diameter: Max. 250 mm

Edge Alignment Accuracy: ±0.5 mm

Line Speed: Max. 60 m/min adjustable

Drying Residual Moisture Content: ≤1 μm

Compressed Air Supply: 0.5–0.7 MPa

Power Supply: Configurable according to local electrical standards

Total Power Consumption: 30 kW

Overall Dimensions: Approx. L6440 × W1200 × H1960 mm

Net Weight: Approx. 2000 kg