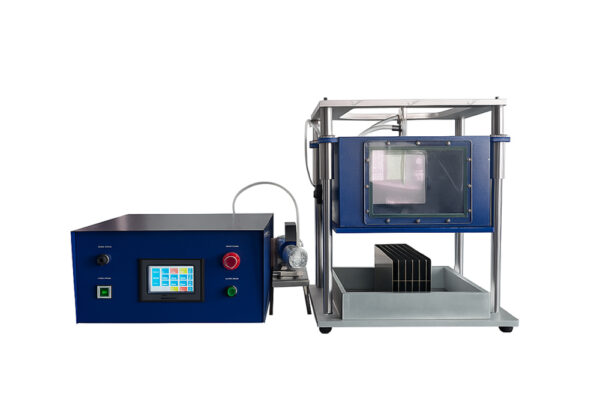

Vacuum Diffusion Chamber And Electrolyte Filling All-In-One Machine

Need a bulk order? Request a competitive quote today!

Model: XE–BZY200

Product Introduction

Suitable for the electrolyte injection and vacuum diffusion process of battery capacitors. It adopts vacuum first, then liquid injection and vacuum standing. The electrolyte has high precision, absorption consistency and high reliability.

Features:

* One machine includes electrolyte filling and diffusion functions;

* High measurement accuracy and repeatability;

* Multi-station with high efficiency, accurate precision, convenient and reliable operation.

* Filling electrolyte after vacuuming, high efficiency, accurate accuracy, convenient and reliable operation;

*Injection accuracy±0.5%, injection volume 0.2 ml ~ 200 ml;

*The entrance and exit are connected by chemical resistant hoses;

*Can be operated in a glove box or dry room;

*The appearance is exquisite and beautiful, and the performance is stable;

*PLC, touch screen operation, flexible parameters, high automation program;

Equipment Main Configuration

Main Components of Equipment*Cylinder and solenoid valve, vacuum components: SMC/Taiwan Airtac*Guide slider: Taiwan Shangyin/Intime*PLC: Display and control*Touch screen: display control*Analog vacuum gauge: Panasonic*Motor: Lei SaiEnvironmental requirements*Ambient temperature: determined by the customer’s factory environment;*Power supply: 220V, 50HZ, voltage fluctuation range: +10%~-10%;*Compressed air: After drying, filtering and stabilizing: the outlet pressure is greater than 4.0kg/cm2; if it is placed in the glove box, the compressed gas used is the same as that in the glove box;*Vacuum source: vacuum pump 2 liters/sec, above -98KPa, or pipeline vacuum (above -98KPa);

| Model | Vacuum Diffusion Chamber And Electrolyte Filling

All-In-One Machine XE–BZY200 |

| Application | Pouch cell & Cylindrical cell |

| Function | Injection and Diffusion |

| Pouch Cell Range | L20~240mm, Tab included,

W20~200mm, gas bag included, T0~15mm |

| Warranty | One year limited warranty with lifetime support |

| Range of Capacity | 0.2ml~200ml |

| Core Liquid Injection | 0.2g~200g |

| Injection Accuracy | ±0.5% |

| Exhalation Velocity | 6ml/s adjustable |

| In and Out Pipe | The liquid inlet pipe 6mm |

| Adjustable Stroke | Maximum X-axis stroke 0~80mm (center) |

| Material | Manufacture of stainless Steel 304 and 316 corrosion-resistant material in key parts |

| External Dimension | L510mm×W400mm×H650mm |

| Power Supply | AC220V/50Hz/0.5KW |

| Weight | 90kg |