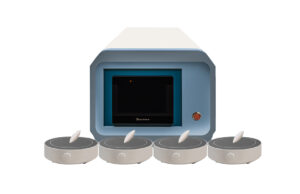

Vertical Planetary Ball Mill

Customization available upon request to meet your specific experimental needs.

Need a bulk order? Request a competitive quote today!

Equipment Introduction

The planetary ball mill is mainly used for mixing, fine grinding, small sample preparation, nano material dispersion, new product development, and small-scale production of high-tech materials. The equipment is compact, fully functional, efficient, and low in noise, making it an ideal equipment for scientific research institutions, universities, and enterprise laboratories to obtain micro and nano-scale powder samples (it can be equipped with four grinding jars simultaneously). It is widely used in fields such as geology, mining, metallurgy, electronics, building materials, ceramics, chemical engineering, light industry, medicine, beauty, environmental protection, and more. It can be used for both dry and wet grinding, and can also be used for mixing and homogenizing various suspensions and pastes.

Working Principle

The XQM series planetary ball mill operates on the principle that each grinding jar (grinding tank) has a fixed rotation and revolution. When the grinding jars rotate around their own axes while revolving around the support disk, the grinding balls inside jars produce strong impact and frictional forces on the sample material due to high-speed movement, achieving ultrafine grinding and mixing. This equipment can be used for dry and wet grinding, as well as vacuum grinding. The final product particle size can reach the nanometer level (approx. 0.1 μm).

Functional Features

◎ Specially suitable for pulverizing, fine grinding, and sample preparation of hard materials, such as ceramics and glass;

◎ Modular design, easy to operate and maintain;

◎ Jars can be used under vacuum conditions for some specific requirements;

◎ Multiple safety protection designs, ensuring safe operation;

◎ Programmable operation (time, forward/reverse rotation, speed, interval);

◎ Supports dry and wet grinding, as well as mixing, homogenizing, mechanical alloying, cell disruption, and colloid grinding;

◎ Flexible programming: adjustable rotation/revolution speed, time, interval pause, forward/reverse rotation;

◎ Excellent sealing performance, no leakage during grinding, smooth and stable operation, low noise, long service life.

Technical Parameters

| No. | Item | Parameter |

|---|---|---|

| 1 | Power supply | AC 110V ±10%, 50Hz |

| 2 | Motor power | 0.25 kW |

| 3 | Jar volume | 100 mL × 4 |

| 4 | Grinding jar material | Optional: agate, nylon, tungsten carbide, stainless steel, zirconia, PTFE, corundum, hard alloy, etc. |

| 5 | Grinding ball material | Optional: agate, nylon, tungsten carbide, stainless steel, zirconia, etc. |

| 6 | Feeding particle size | Material particle size ≤10 mm, recommended ≤3 mm |

| 7 | Output particle size | Up to 0.1 μm |

| 8 | Speed range (R/min) | Revolution: 45–435 rpm; rotation: 90–870 rpm |

| 9 | Speed control mode | Stepless speed regulation, forward/reverse rotation, automatic reversal |

| 10 | Operation mode | Two or four jars can operate simultaneously |

| 11 | Continuous working time | 72 hours |

| 12 | Program control | Programmable operation, set forward/reverse rotation time (0–99 min), interval pause time (0–99 min), cycle operation |

| 13 | Safety protection | Equipped with safety interlock, stops automatically when the cover is opened |

| 14 | Dimensions | L500 mm × W300 mm × H340 mm |

| 15 | Net weight | 29 kg |

Consumable Parts List

| No. | Name | Specification | Brand | Quantity |

|---|---|---|---|---|

| 1 | Grinding jars | 100 mL | — | 4 pcs |

| 2 | Grinding balls | 0.15 kg/set | — | 4 sets |

Packing List

| No. | Name | Quantity | Unit | Remarks |

|---|---|---|---|---|

| 1 | Equipment | 1 | set | |

| 2 | Grinding jars | 4 | pcs | 100 mL each |

| 3 | Grinding balls | 4 | sets | 0.15 kg/set |

| 4 | User manual | 1 | copy | Paper file |

| 5 | Product certificate | 1 | copy | Paper file |

| 6 | Power cord | 1 | pcs | |

| 7 | Inner hex wrench | 1 | pcs |

Maintenance and Notes

◎ Clean the jars and balls thoroughly after each use to prevent cross-contamination;

◎ Regularly inspect the condition of wearing parts and replace as necessary to maintain performance;

◎ When opening or disassembling the equipment, strictly follow the safety instructions in the manual to prevent personal injury.