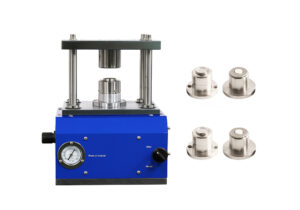

Electric Coin Cell Crimping Machine

Customization available upon request to meet your specific experimental needs.

Need a bulk order? Request a competitive quote today!

1. Product Introduction

Mainly used for sample preparation of coin cells in laboratory battery material R&D, as well as for sealing capacitor cases. It can also be used for small-scale pilot production. Using electric-driven sealing force, and with different molds, it can also be used for tablet pressing, powder pressing, molding, and clamping operations.

2. Mold Configuration

The standard mold is suitable for CR20 series coin cells. By replacing certain mold components, it can also be configured for sealing CR2450, CR2430 series coin cells, and for disassembly molds.

3. Main Features

◎ Touch screen operation, parameter setting, and adjustable automation level;

◎ Adjustable and displayable sealing pressure value;

◎ The glove box pass-through design (360° smooth transition port) allows direct transfer without contamination (sliding rail), compact size, easy to operate;

◎ Electric drive sealing mode, no vibration during cell sealing, no leakage;

◎ Precision-designed mold ensures reliable forming accuracy. The robust steel structure design ensures operational stability and safety;

◎ Compact size, easy to operate, can be operated inside a glove box;

◎ Simple appearance, easy maintenance, small footprint, easy to use, and high forming accuracy.

4. Technical Parameters

◎ Sealing Pressure Control: Precision digital control, freely adjustable via digital input;

◎ Power Supply: Single-phase 110V–220V AC ±10%, frequency 50Hz/60Hz; power 100W;

◎ Sealing Pressure: Max. 1200 kgf (approx. 12 kN), digitally adjustable;

◎ Sealing Stroke: 20 mm;

◎ Sealing Mold: Standard equipped with CR20 mold (CR2016, CR2025, CR2032 optional), other molds customizable;

◎ Dimensions: L250 mm × W185 mm × H450 mm;

◎ Weight: Approx. 25 kg.

5. Maintenance and Precautions

-

Frequently clean the guide posts and other moving parts to remove dirt, keep clean, and lubricate to maintain smooth operation.

-

When not using the electric crimping machine, turn off the power supply and return the mold to its initial position. If not used for a long period, disassemble the upper mold screws and clean the sealing mold surface, apply oil or anti-rust oil to keep the mold surface smooth and clean.

-

Regularly check and tighten all screws, nuts, bolts, and pins on the electric crimping machine to prevent loosening and ensure safety.

-

Strictly avoid touching the guide posts, sliding plates, or sealing area during operation to prevent injuries in hazardous zones.

-

Do not allow untrained or unauthorized personnel to operate the machine to avoid accidents or damage.