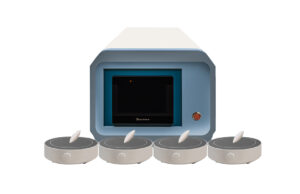

Automatic Slitting and Cutting Machine XN-ARSC-300

Need a bulk order? Request a competitive quote today!

Product Introduction

This machine is mainly used for automatic cutting of battery cathode and anode electrode sheets. It supports flexible setting of cutting length, quantity, and speed, and can operate in both standalone and fully automatic modes. The system enables automatic unwinding, automatic tension control, automatic cutting, and automatic stop, making operation simple and efficient. It is suitable for processing aluminum foil and copper foil electrode materials with high cutting accuracy and productivity.

Product Features

Cutting length, quantity, and speed can be freely set, supporting independent cutting operations.

Automatic tension control during unwinding ensures stable and consistent material feeding.

Supports continuous cutting with options for fixed-length cutting or photoelectric tracking cutting, adapting to different process requirements.

Compatible with both roll-to-sheet cutting and post-calendering cutting processes.

Wide cutting range with adjustable width from 10–300 mm and adjustable cutting length from 1–9999 mm.

PLC control system with HMI interface enables convenient operation and parameter adjustment.

Compact industrial design with clean appearance and stable structure.

Easy operation with high safety and small footprint.

Main Specifications

Unwinding Mode: Pneumatic shaft unwinding with automatic tension control

Fixed-Length Cutting Speed: 5–250 mm/s

Tracking Cutting Speed: 5–150 mm/s

Maximum Unwinding Diameter: 250 mm

Material Thickness: ≤ 25 μm

Power Supply: Configurable according to local electrical standards

Power Consumption: 500 W

Compressed Air Supply: 0.5–0.8 MPa

Applicable Width: Maximum 300 mm

Cutting Length Range: 1–9999 mm

Cutting Accuracy: Length tracking and precision control enabled, adjustable cutting accuracy up to ±0.3 mm

Overall Dimensions: Approx. L1250 × W720 × H915 mm (guide rail length 800–1500 mm optional)

Net Weight: Approx. 240 kg