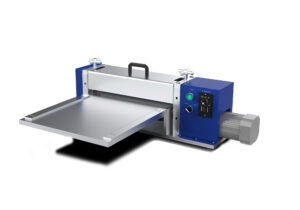

Cylindrical Battery Semi-Automatic Winding Machine

Need a bulk order? Request a competitive quote today!

Model: XE-SJR (18650, 21700, 26650 & 32650)

Profile:

Semi-Automatic Winding Machine is mainly used for the precision winding of core of the cylinder battery. This machine can be applied for 18650, 21700, 26650 and 32650 together

Working Process

Manually guide the cathode and anode electrodes into the winding part, and separated stacking with the separator, and the winding will be carried out according to the requirements of the process, automatically attaching the termination tape, and the cell will automatically feed.

Function and Features

- Adopt single needle counterwinding needle structure.

- Manual lead-in electrode, automatic winding, automatic change needle, automatic tape ending tape and automatic unloading;

- The adhesive tape adopts the horizontal paste (the tape is perpendicular to the tab), the adhesive is flat, and the adhesive position can be controlled accurately without tightening the cell; the adhesive is stable and reliable;

- winding needle speed was adjustable;

- Two rolls of separator active to unwinding, tension push switch control technology can adjust tension automatically during winding.

- It has a dust removal device;

- Separator outer pack end.

- The cell after winding without damage, core pulling and electrode dislocation phenomenon;

- Easy to operate,adjust and replace;

Technological Process:

The equipment meets the winding process standard of cylindrical lithium-ion battery: the diaphragm completely wraps the negative sheet, and the negative sheet wraps the positive sheet. The process flow is as follows:

1) Diaphragm pre coiling: Adopting tooth cutter technology can save the length of pre coiling diaphragm;

2) Draw in the negative electrode: Manually guide the negative electrode sheet into the winding part; Draw in the positive electrode: Manually guide the positive pole piece into the winding part;

3) Winding;

4) Shift station;

5) Cut off the diaphragm, paste the termination glue and blanking.

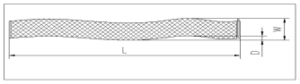

| D | W | L | |

| Tolerance(mm) | < 0.5 | < 0.3 | < 1000 |

Main Components of Equipment:

1) The equipment is composed of winding device, station changing device, diaphragm unwinding device, pole piece guide device, glue pasting device, blanking device and control system.

2) Winding device (two sets): Composed of single head opposite threading to ensure winding accuracy and convenient replacement of winding needle.

3) Station moving device (one set): Used for the conversion of winding station and gluing station.

4) Diaphragm unwinding device (two sets): Diaphragm coil active unwinding air pressure regulation control.

5) Pole piece guide device (two sets): Unilateral adjustment, convenient adjustment.

6) Gluing and blanking device (one set).

Material specifications (unit: mm)

Consumable Parts and Warranty Time

| Material | Length | Width | Thickness | Inner Diameter | Outer Diameter |

| Cathode Electrode | 600~2000 | 48-137 | 0.1-0.2 | ||

| Anode Electrode | 600~2000 | 48-137 | 0.1-0.2 | ||

| Separator | Roll material | 50-140 | 0.016-0.045 | 76.2 | 250 |

| Termination Ttape | Roll material | 10-90 | 0.01-0.035 | 76.2 | 150 |

| Model | XE-SJR (18650, 21700, 26650 & 32650) | ||||

| Voltage | AC220V,1.5KVA,50HZ | ||||

| Compressed air | 0.4-0.6MPa | ||||

| Productive capacity | 8PCS/min | ||||

| Weight | About 500kg | ||||

| Size | 1750mm*1350mm*1570mm

(Does not include the outstretched length of the electrode.) |

||||

| Winding needle specification | Φ3mm-Φ12mm(With one set for free, customized) | ||||

| Applicable outer diameter of the cell | Φ8mm-Φ32mm | ||||

| Equipment capacity | 6~15 pcs/ min (according to the length/width of the electrode) | ||||

| Winding precision | when the electrode is guaranteed to meet the following conditions:

The width error is less than ±0.2mm; The bending error of “S” is less than ±1mm/500mm; The tower shape error of the separator is less than ±0.2mm; |

||||

| The winding precision can be satisfied | The alignment error of the separator is less than ±0.5mm;

The alignment error of electrode is less than ±0.5mm; It can realize the negative electrode wrap the cathode electrode , the separator wrap negative electrode, and the alignment of the finished product section is ±0.5mm |

||||

| Qualified rate | ≥98% (excluding equipment factors) | ||||

| Warranty | One Year limited warranty with lifetime support | ||||

| Name | Specification (mm) | Warranty Time | Remarks | ||

| Winding Machine | Complete machine

1 year |

Except for human factors

(Lifelong maintenance) |

|||

| Gummed Paper Cutter | 3 months | Recommend to buy a spare | |||

| Rolling Needle | 3 months | Except for human factors

Recommend to buy a spare |

|||

| Photoelectric Eye | 6 months | Crash and oil inlet are not guaranteed | |||

| Synchronous Belt | 1 year | Oiling is not guaranteed |