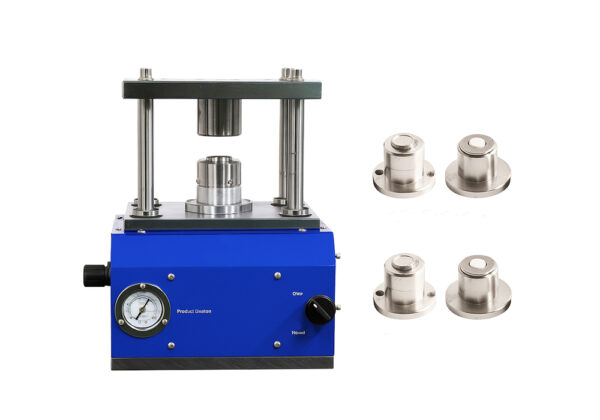

Electric Coin Cell Crimping Machine for Lab Button Battery Sealing

Need a bulk order? Request a competitive quote today!

Model: XE-DF160

Profile:

It is mainly used in the production of samples of laboratory battery materials for button batteries, capacitor scientific research sealing, and can also be used for small-scale trial production in factories. The electric method saves effort, and different molds can also be used for dry powder tabletting, wet powder tabletting, pressing molding, riveting and other operations.

Mold:

Standard configuration can be used for the CR20XX series coin cells such as CR2016, CR2025, and CR2032. Replace some of the mold parts can crimping 2450, 2430 and other button batteries, as well as disassemble the mold.

Features :

* Touch screen operation, easy parameter setting and high degree of automation;

* Can set and display sealing pressure value.

* If there is no obstacle (skateboard) in the glove box Φ360 transition bin, it can pass directly through the transition bin, with small volume and easy operation

* Electric drive, no vibration on battery seal, no leakage;

* Precise mold design guarantees accurate and reliable seal forming, solid steel structure design, stable and safe use;

* Small size, convenient operation, can be operated in glove box;

* Beautiful appearance, easy maintenance, small volume, easy operation, accurate molding etc.

Technical Specifications:

- Frequently wipe the dirt on the guide post and other moving parts, keep it clean, and lubricate to keep the movement smooth.

- When the electric sealing machine is not used, turn off the power and return the movable template to the initial position. If it is not used for a long time, remove the upper mold screw and take out the sealing mold for cleaning, and apply oil to keep the sealing molding surface clean and smooth.

- Regularly check the screws, nuts, pins and other fasteners on the electric sealing machine to prevent loosening and prevent machine quality accidents and personal accidents.

- It is strictly forbidden to extend your hands and other parts to the dangerous area of the guide post, slide, and sealing during operation to cause personal injury. Do not allow two or more people to operate during operation to avoid accidental injury.

| Model | Electric Crimping Machine for Coin Cell XE-DF160 |

| Voltage | Single-phase voltage 110V ~ 220V AC ± 10%;

frequency 50Hz / 60Hz |

| Power | 100W |

| Sealing Pressure | Max. 1200Kg, digital display can be set |

| Sealing Stroke | 20mm |

| Sealing Mold | CR20 crimping mold (CR2016, CR2025, CR2032),

other molds are optional |

| Structure | Heavy Duty Steel Platform |

| Dimension | L250*W185*H450 mm |

| Weight | 25kg |

| Warranty | One Year limited warranty with lifetime support |

| Maintenance

Notes |

Electrolytes are highly corrosive materials, and therefore the

die set must be cleaned with alcohol after each use to avoid corrosion and to maintain the equipment’s integrity. |

| Optional | Protection shield/enclosure with the implementation of

the safety interlock |