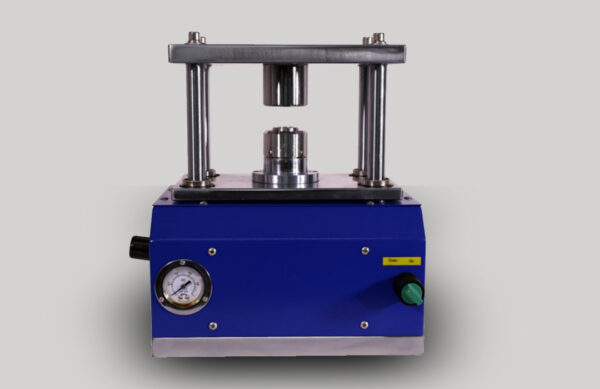

Pneumatic Coin Cell Crimping Machine

Customization available upon request to meet your specific experimental needs.

Need a bulk order? Request a competitive quote today!

1. Product Introduction

Mainly used for laboratory battery material R&D sample preparation to assemble coin cells, capacitor cases, and also for small-scale pilot production in factories. With different molds, it can also be used for battery disassembly, electrode sheet pressing, and battery powder pellet pressing.

2. Standard Mold Configuration

Equipped with a standard mold for CR20 series coin cells. By replacing some mold components, it can also be used to seal CR16, CR24, CR30 series coin cells, etc.

3. Main Features

◎ The lower mold adopts a high-precision limit ring to control the sealing height of the battery cell, preventing excessive or unstable sealing pressure that may damage the cell or sealing cup;

◎ The upper mold and inner ring adopt a screw-spring ejection structure to ensure that the cell is not stuck inside the mold after sealing; it can be easily removed by turning the top screw knob;

◎ The crimping air supply can be provided by either gas cylinders or compressors, and the exhaust design prevents damage to glove boxes;

◎ Precision-designed molds ensure reliable sealing and forming accuracy. The robust steel structure design ensures stability and safety during use;

◎ Purely pneumatic operation, no electricity required, easy to operate and convenient.

4. Technical Specifications

◎ Air Source: 0.6–0.8 MPa nitrogen, argon gas cylinder, or compressed air (not recommended to use compressed air inside a glove box);

◎ Exhaust Design: Specially designed exhaust port, can be externally connected via KF40 or similar fittings;

◎ Gas Consumption: Approximately 480 mL per sealing cycle;

◎ Sealing Pressure: Controlled by manual regulating valve, maximum pressure 1 MPa, recommended operating pressure 0.7 MPa, accuracy within ±0.5%;

◎ Sealing Stroke: 30 mm;

◎ Sealing Die: Standard CR20 die, other sizes optional or customizable;

◎ Disassembly Die: Optional or additional dies for CR16, CR20, CR24, CR30, etc.;

◎ Dimensions: L290 mm × W205 mm × H330 mm;

◎ Weight: Approx. 25 kg;

◎ Safety Feature: Equipped with short-circuit prevention function for battery sealing;

◎ Material: High-strength steel, surface treated with anti-corrosion nickel plating and spraying for permanent rust prevention.