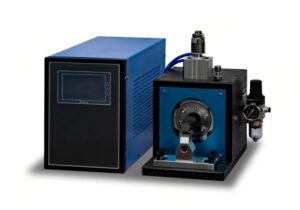

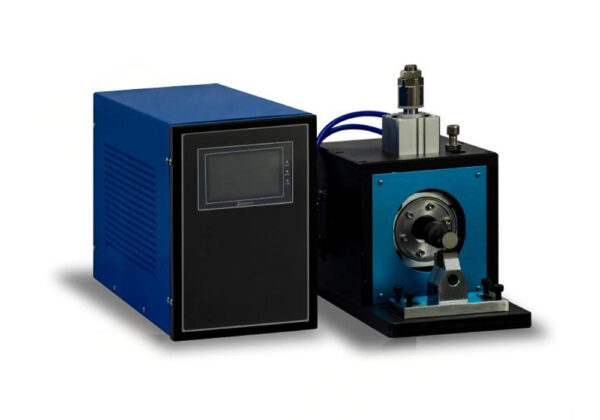

Ultrasonic Spot Welder XN-UMW-2000

Need a bulk order? Request a competitive quote today!

Product Introduction

The RSC-UMW-2000 Ultrasonic Spot Welder is designed for metal welding applications in battery tab welding, foil welding, and thin metal joining processes. Featuring a compact structure, user-friendly operation, and stable performance, it provides reliable ultrasonic welding without the need for flux, additives, or pre-treatment. The system is well-suited for laboratory research, pilot production, and precision manufacturing.

Product Features

Touch-screen interface for intuitive operation, with automatic frequency tracking

Flux-free welding process; ultrasonic vibration removes surface contamination and oxide layers naturally

No pre-treatment required; welding can be completed without solder or chemical additives

High welding efficiency with short welding cycle time (typically 0.1–2.5 seconds per weld)

Low heat input; welding temperature remains well below the metal melting point, preserving material properties

Excellent electrical conductivity after welding with low contact resistance

Strong and consistent weld strength with good repeatability

Low noise, low vibration, easy operation, and minimal maintenance

Safe operation without smoke, sparks, or harmful emissions

Main Specifications

| Item | Specification |

|---|---|

| Applicable Materials | Copper foil / Aluminum foil |

| Power Supply | Configured according to local electrical standards |

| Operating Air Pressure | 0.5 – 0.7 MPa |

| Ultrasonic Frequency | 20 kHz (automatic frequency tracking) |

| Output Power | 2000 W (adjustable) |

| Welding Time | 0 – 15 s |

| Max. Weld Spot Size | ≤ 5 mm |

| Welding Layers | Up to 5–40 layers |

| Drive Mode | Pneumatic |

| Welding Material (Cathode) | Aluminum foil, 0.015 – 0.020 mm |

| Welding Material (Anode) | Copper foil, 0.009 – 0.012 mm |

| Welding Material (Busbar) | Copper foil, 0.1 – 0.2 mm |

| Control Unit Dimensions | Approx. L360 × W200 × H480 mm |

| Welding Head Dimensions | Approx. L460 × W200 × H270 mm |

| Weight | Approx. 60 kg |